Fast and Quality Service

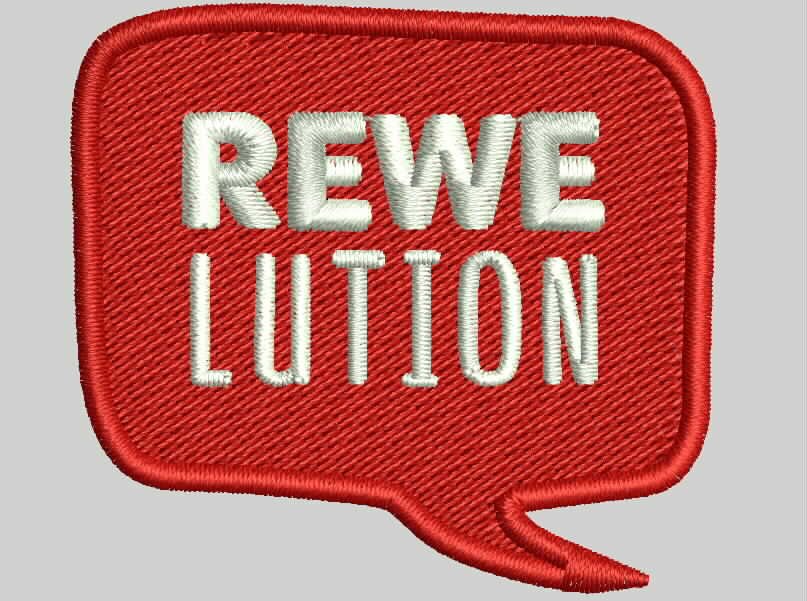

Patches Digitizing Service

Introduction to Patches Digitizing Service:

Patches digitizing service is a specialized offering that involves converting designs into a digital format compatible with embroidery machines, specifically tailored for creating patches. This service is essential for achieving precise and detailed embroidery on patch materials.

Digitizing Process for Patches:

The process commences with the conversion of the chosen design into a digital format using advanced software. This digitized file serves as the blueprint for the embroidery machine, containing precise instructions on stitch types, densities, and color placements specific to patch materials.

Patch Material Considerations:

Patches can be made from a variety of materials, including twill, felt, or other fabrics. Each type requires specific digitizing techniques to ensure that the embroidery is not only visually appealing but also adheres securely to the patch material. The digitizer must account for the texture and thickness of the chosen material.

Density and Stitch Type Adjustments:

Given the unique characteristics of patches, adjustments in stitch density and type are crucial. These parameters are fine-tuned to accommodate the thickness and texture of the material while ensuring that the embroidery maintains clarity and definition.

Thread and Color Selection:

Thread selection is particularly important for patch digitizing. The choice of thread type and color impacts both the visual appeal and durability of the embroidery. Specialized threads may be used to enhance the design's texture and longevity, especially for patches subjected to frequent use.

Testing and Quality Assurance:

Before full-scale production, a sample patch is used for testing. This allows for a thorough evaluation of how the digitized design interacts with the specific patch material. Adjustments are made as necessary to ensure the final embroidered patch meets the highest quality standards.

Final Production and Inspection:

Once the digitized design is perfected, the embroidery process begins. The patch material is securely hooped and positioned on the embroidery machine, which then follows the precise instructions from the digitized file. The finished patches undergo a comprehensive inspection, checking for loose threads, color accuracy, and overall design quality.

Patches digitizing service is a specialized craft that demands expertise in both design and embroidery techniques. With our skilled digitizers and advanced equipment, we guarantee that your patch embroidery project will be executed with the utmost care and expertise, resulting in high-quality embroidered patches.

Top quality

Mix and match

Shipping worldwide

How it works?

Patches Digitizing Embroidery Process

The process of digitizing patches for embroidery involves several intricate steps to ensure the final product is of the highest quality.

First, the chosen design is imported into specialized digitizing software. This software serves as a digital canvas where the design is meticulously transformed into a series of precise instructions for the embroidery machine.

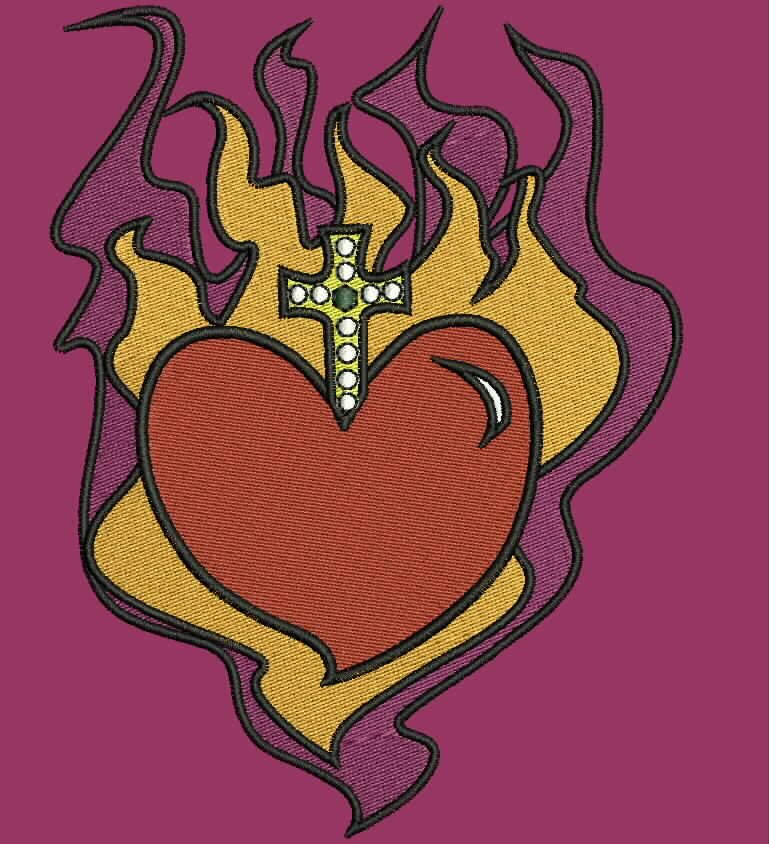

Next, the digitizer carefully selects the appropriate stitch types and parameters. For patches, a combination of fill stitches and satin stitches is often used. Fill stitches create a solid background, providing stability to the design, while satin stitches add a polished finish to the edges.

Stitch density is a critical consideration. It dictates the spacing between stitches, affecting the overall appearance of the embroidery. Striking the right balance ensures that the design is neither too dense, which can lead to a bulky result, nor too sparse, which might allow the fabric to show through.

Thread colors are chosen to match the original design. This involves referencing a comprehensive thread color chart, which provides a wide range of options. Careful attention is paid to ensure that the chosen threads align with the design’s color scheme, creating a visually accurate representation.

The digitizer then fine-tunes the digitized design, adjusting for clarity and detail. This step is particularly important for intricate designs, ensuring that every element is well-defined and will translate accurately during embroidery.

Once the design is digitized and refined, it undergoes testing on a sample patch material. This allows for a thorough evaluation of how the digitized design interacts with the specific material. Adjustments are made as necessary to fine-tune the design for optimal results.

Finally, the digitized design is loaded onto the embroidery machine, and the patches are embroidered. Skilled technicians monitor the machine to ensure it operates smoothly and that the design is being executed accurately. The choice of thread material and color, as determined during the earlier stages, plays a significant role in the final appearance of the embroidered patch.

In conclusion, patch digitizing for embroidery is a meticulous process that demands expertise and attention to detail. Each step, from digitizing to testing and embroidering, is carefully executed to ensure that the final embroidered patches meet the highest quality standards. This commitment to craftsmanship and precision is a testament to the dedication to delivering high-quality embroidered patches.

Logo Design Preparation

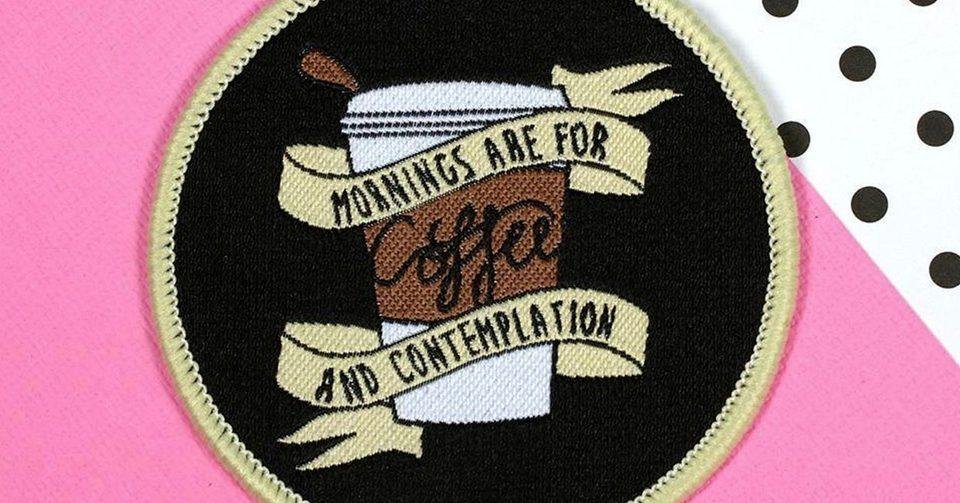

Preparing a logo for patch digitizing involves a series of careful steps to ensure the final embroidery is both visually striking and well-executed on the specific patch material. Firstly, the original logo design is thoroughly examined to determine its suitability for patch digitizing. Intricate or highly detailed designs may need to be simplified for effective embroidery, especially on certain patch materials. Next, the design is translated into a digital format using specialized software. This digitized file serves as a blueprint for the embroidery machine, providing precise instructions for the stitching process. Skilled digitizers carefully plot out each stitch, considering the density, stitch type, and sequence to ensure the design is faithfully represented. Considering patch materials can vary from twill to felt or other fabrics, the choice of material is crucial. Each type requires specific digitizing techniques to ensure that the embroidery is not only visually appealing but also adheres securely. Color selection is also vital. Digitizers choose thread colors that closely match the original logo, ensuring that the embroidered logo complements the patch material. Finally, the digitized design undergoes a test run on a sample patch to evaluate its compatibility with the specific material. Any necessary adjustments are made to fine-tune the design for optimal results. In summary, logo design preparation for patch digitizing requires a combination of artistic vision and technical expertise. It's a meticulous process that sets the stage for a visually striking and well-executed embroidered logo. With expert digitizers and advanced software, we ensure that your patch embroidery project will make a lasting impression.

Stitching Parameters

Determining the right stitching parameters is a critical aspect of patch digitizing. It involves making precise adjustments to ensure that the embroidery is not only visually appealing but also secure and durable on the patch material. The choice of stitch type plays a significant role. For patches, a combination of fill stitches and satin stitches is often employed. Fill stitches create a solid background, providing stability to the design. Satin stitches, on the other hand, add a polished finish to the edges, enhancing the overall look. Stitch density is another crucial parameter. It dictates the spacing between stitches, affecting the overall appearance of the embroidery. Too much density can lead to a bulky, uneven result, while too little density might cause the fabric to show through. Moreover, adjusting stitch length is vital for achieving the desired texture and coverage. Shorter stitches create a denser appearance, while longer stitches can provide more open spaces within the design. Underlay stitches are also considered in patch digitizing. These foundational stitches are placed beneath the top layers to stabilize the fabric and ensure a smooth, even surface for the embroidery. Thread tension is meticulously adjusted to prevent any puckering or distortion of the patch material. Proper tension ensures that the stitches lie flat and securely on the fabric. Color changes in the design are carefully planned. Each change requires a precise stop and start point to maintain a clean and seamless transition between colors. Ultimately, getting the stitching parameters right is an art in itself. It requires a keen eye for detail and a deep understanding of the patch material's characteristics. With the right adjustments, the embroidered patch will not only look visually appealing but will also be durable and long-lasting. This attention to stitching parameters is a testament to the commitment to delivering high-quality embroidered patches in patch digitizing.

Embroidering

Embroidering is the culmination of the patch digitizing process, where the carefully crafted digital design is translated into physical form on the patch material. The process begins by securely hooping the patch material and positioning it on the embroidery machine. This ensures that the material remains stable and taut throughout the embroidery process. Precision in hooping is crucial to ensure that the design is accurately placed on the patch. Next, the digitized design is loaded onto the embroidery machine. This digital file serves as a blueprint, providing precise instructions on stitch types, densities, and color placements. As the machine begins its work, it follows these instructions meticulously, executing each stitch with precision. The embroidery machine uses a needle and thread to replicate the digital design on the patch material. The machine's needle penetrates the material, pulling the thread through in a series of carefully calculated movements. This process is repeated for each stitch, gradually building up the design. Throughout the embroidery process, skilled technicians monitor the machine to ensure that it operates smoothly and that the design is being executed accurately. They may make minor adjustments as needed to maintain optimal results. The choice of thread material and color, as determined during the earlier stages of patch digitizing, plays a significant role in the final appearance of the embroidered patch. Each thread color is meticulously chosen to match the original design, ensuring a faithful representation.

Digitizing Software

Choosing the right digitizing software is crucial for achieving high-quality results in patch digitizing. A proficient software tool streamlines the process, allowing for precise control over stitch placement and design intricacies. One of the most popular and versatile digitizing software options is Wilcom's Embroidery Studio. It provides a comprehensive suite of tools for digitizing various types of designs, including patches. Its intuitive interface and advanced features make it a top choice for professional digitizers. Pulse DGSTM is another powerful software solution widely used in the embroidery industry. It offers a range of tools for creating intricate designs, making it suitable for the detailed work often required in patch digitizing. For those looking for a user-friendly option, Hatch Embroidery provides a user-friendly interface without sacrificing functionality. It caters to both beginners and experienced digitizers, making it a versatile choice for patch digitizing. For open-source enthusiasts, Ink/Stitch is a popular choice. This free, open-source extension for Inkscape allows users to create embroidery designs, making it a cost-effective option for patch digitizing. Finally, Embird is a well-regarded software solution that offers both embroidery editing and digitizing capabilities. It's known for its user-friendly interface and affordable pricing, making it accessible to a wide range of users. Ultimately, the choice of digitizing software will depend on individual preferences, budget considerations, and specific project requirements. Regardless of the software chosen, mastering its tools and features is essential for achieving high-quality results in patch digitizing.

Color Selection

Selecting the right colors is a crucial step in patch digitizing. It involves careful consideration of the original design and the patch material to ensure the embroidered logo complements the overall aesthetic. The process begins with a thorough examination of the design's color palette. Each hue and shade is assessed to determine how they will translate into embroidery. Special attention is given to any gradients or shading, as these may require creative use of thread colors to achieve the desired effect. Next, the digitizer selects thread colors that closely match the original design. This involves referencing a comprehensive thread color chart, which provides a wide range of options. Careful attention is paid to ensure that the chosen threads align with the design's color scheme, creating a visually accurate representation. In some cases, blending threads or using variegated threads may be employed to achieve specific effects, such as shading or texture. These techniques require a keen understanding of color theory and thread properties to ensure a seamless transition between hues. Additionally, the choice of thread material can impact the final result. Different materials, such as rayon or polyester, may have slight variations in color appearance. Experienced digitizers take these factors into account when making their selections. Ultimately, color selection is a meticulous process that demands a keen eye for detail and a deep understanding of how colors interact in embroidery. The goal is to ensure that the embroidered patch accurately represents the original design, creating a visually appealing and aesthetically pleasing result. This attention to color selection is a testament to the commitment to delivering high-quality embroidered patches in patch digitizing

Finishing

The finishing phase in patch digitizing is a critical step that ensures the embroidered patches are of the highest quality and ready for use. This phase encompasses several key processes that add the final touches to the patches. First and foremost, any loose threads or imperfections are carefully trimmed and removed. This meticulous attention to detail ensures that the final patch looks clean and polished. Any stray threads that may have occurred during the embroidery process are expertly addressed. Next, the patches undergo a thorough quality check. This involves a close examination of each patch to ensure that the embroidery is precise, the colors are accurate, and there are no visible flaws. Any patches that do not meet the rigorous quality standards are set aside for rework or adjustments. If required, backing material may be added during the finishing phase. This backing provides additional support and stability to the patch, making it more durable and long-lasting. The choice of backing material is carefully considered to ensure it complements the patch material and design. Once the patches have undergone these meticulous finishing steps, they are ready for packaging and distribution. Each patch is carefully inspected one final time to ensure it meets the highest quality standards. It is then carefully packaged to protect it during transit, ensuring that it arrives in pristine condition. The finishing phase exemplifies the commitment to delivering high-quality embroidered patches in patch digitizing. It is a testament to the dedication to craftsmanship and attention to detail that sets these patches apart. Each patch is a work of art, meticulously crafted to meet the highest quality standards and exceed customer expectations.

Importing and Editing

Importing and editing are critical steps in the patch digitizing process, allowing for precise customization of the design before it's embroidered onto the patch material. The process starts by importing the chosen design into the digitizing software. This design can be in various file formats, such as SVG, PNG, or JPEG. Once imported, the software converts it into a format compatible with embroidery machines. The imported design may need resizing to fit the dimensions of the patch accurately. This step ensures that the design will be proportionate and visually appealing once embroidered. Additionally, the position of the design on the patch is carefully determined to ensure it's centered and aesthetically pleasing. Before proceeding with further edits, the design is digitized. Skilled digitizers use specialized software to convert the design into a digital format. This digital file provides precise instructions for the embroidery machine, specifying stitch types, densities, and color placements. Next, the design undergoes a meticulous editing process. This involves adjusting various parameters to enhance clarity and detail. For intricate designs, this step is particularly critical to ensure that every element is well-defined and will translate accurately during embroidery. Thread colors are chosen to match the original design. This step is crucial for achieving an accurate representation of the design, ensuring that the embroidered logo complements the patch material. Once the design is edited and digitized, it's tested on a sample patch material. This allows for a thorough evaluation of how the digitized design interacts with the specific material. Adjustments are made as necessary to fine-tune the design for optimal results. After successful testing, the edited and digitized design is ready for full-scale production. It's securely hooped and positioned on the embroidery machine, which then follows the precise instructions from the digitized file.

Testing

Testing is a crucial phase in the patch digitizing process, serving as a quality assurance step before full-scale production. It involves evaluating how the digitized design interacts with the specific patch material to ensure optimal results. A sample patch is used for this purpose. The digitized design is carefully embroidered onto the sample material using the chosen threads and stitching parameters. This allows for a thorough assessment of various elements, including stitch density, thread tension, and color accuracy. During testing, digitizers pay close attention to the clarity and detail of the embroidered design. Any adjustments needed to enhance these aspects are noted and implemented before proceeding with the final production run. Additionally, the sample patch undergoes rigorous inspection for any imperfections or inconsistencies. This includes checking for loose threads, uneven stitching, or any deviations from the original design. The sample patch also provides an opportunity to assess the overall durability and stability of the embroidery on the chosen patch material. This is particularly important to ensure that the final patches will withstand wear and tear over time. If any issues or discrepancies are identified during testing, digitizers make the necessary adjustments to the digitized file. This might involve fine-tuning stitch parameters, revising thread color selections, or making other refinements to achieve the desired result. Ultimately, the testing phase is a critical step in ensuring that the final embroidered patches meet the highest quality standards. It exemplifies the dedication to delivering meticulously crafted patches in patch digitizing, and it ensures that each patch will be a true representation of the original design.

Quality Check

The quality check process in patch digitizing is a crucial step that ensures every embroidered patch meets the highest standards of craftsmanship. It involves a series of meticulous examinations to guarantee that the final product is flawless. First, each patch undergoes a visual inspection. This involves a close examination of the embroidery to ensure that every stitch is precise and well-defined. Skilled technicians scrutinize the patch for any loose threads, uneven stitching, or deviations from the original design. Next, the colors are carefully evaluated. The thread colors are compared to the original design to confirm that they match accurately. This step is crucial to ensure that the embroidered logo complements the patch material and maintains the integrity of the original artwork. The patch material itself is also inspected. Technicians check for any imperfections, discolorations, or irregularities in the fabric. Any patches that do not meet the stringent quality standards are set aside for rework or adjustments. In addition to visual inspections, the patches may undergo tactile evaluations. This involves running fingers over the embroidery to ensure that the stitches are secure and even. It also allows technicians to detect any anomalies that may not be immediately visible. The patches are also assessed for durability and stability. This involves tugging and gently flexing the patch to ensure that the embroidery is securely affixed to the material. This step is crucial to guarantee that the patches will withstand wear and tear over time.

Patches Embroidery

Patches embroidery is a specialized form of textile decoration where a design or logo is stitched onto a fabric patch. These patches are then typically sewn or attached onto garments, bags, hats, or other items.

The process involves several key steps

Design Creation: The first step is to create or choose a design that will be embroidered onto the patch. This can be a logo, emblem, artwork, or any other graphic

Digitization: The chosen design is then digitized using specialized software. This process converts the design into a digital format that the embroidery machine can read. It also involves setting parameters for stitch type, density, and other details

Color Selection: The thread colors are chosen to match the original design. This ensures that the embroidered patch accurately represents the original artwork

Testing: The digitized design is tested on a sample patch material. This allows for adjustments to be made to fine-tune the design for optimal result

Embroidering: Once the design is digitized and tested, it is loaded onto the embroidery machine. The machine follows the instructions from the digitized file, stitching the design onto the patch materia

Quality Check: The embroidered patches undergo a thorough quality check. This involves inspecting each patch for any imperfections, loose threads, or deviations from the original design

Trimming and Finishing: Any loose threads or imperfections are carefully trimmed and removed. This ensures that the final patch looks clean and polished

Backings (optional): Depending on the intended use, backing material may be added to provide additional support and stability to the patch. This is especially important for patches that will be frequently handled or attached to high-wear items

Packaging and Distribution: The finished patches are carefully packaged to protect them during transit. They are then ready to be distributed or attached to garments or other items.

Patches embroidery is a versatile and popular method of branding and customization. It’s used by various organizations, including military, sports teams, businesses, and hobbyist groups, to create distinctive and personalized items. The quality and precision of patches embroidery depend on the expertise of the digitizer and the capabilities of the embroidery equipment used.